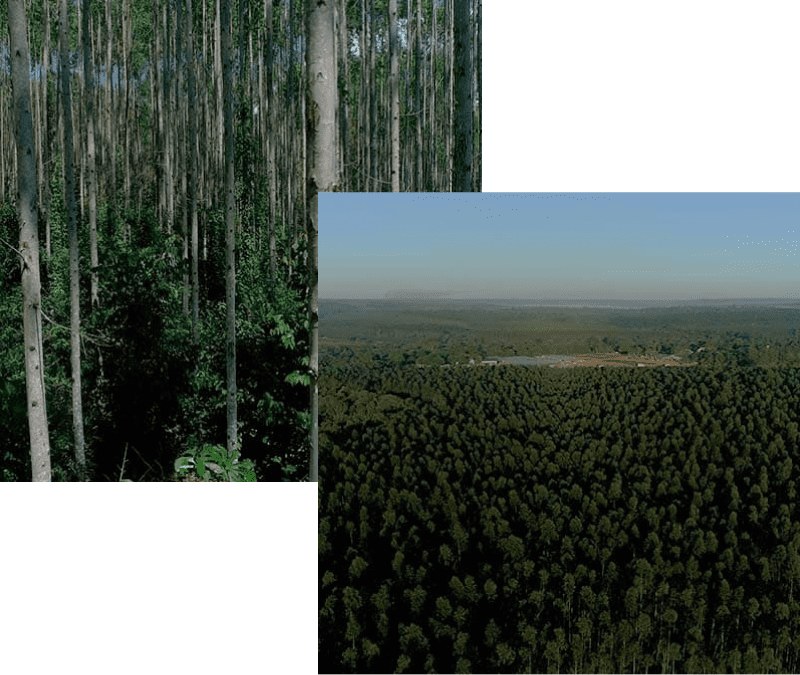

Flora Industrial Ltda bases its activities on environmental sustainability, since it uses only raw material originating from areas reforested with Eucalyptus that total more than 30 thousand hectares, thus signing the governmental pact established to eliminate the level of deforestation in the region, showing that it is possible to achieve economic growth in an ethical and responsible manner.

There are 500,000 eucalyptus seedlings planted per month, which is equivalent to 6 million trees planted per year. The planting area is 30 thousand hectares, of the 110 thousand hectares of native forest preserved and owned by Flora.

With such a great commitment to protecting nature, Flora was recognized and awarded by state and national programs to protect the environment. A highlight is the generation of energy from waste, installed at the Flora Company, which won first place in the State of Pará for its national participation in the “Economic Energy Award”.

The Concrem Group was recognized by Rank Brasil in 2006, as the largest reforester of native trees in the Amazon of the Paricá species. The company received the Referencia Award for the second time from the Referência magazine in 2003 and 2007 and was also honored by the government of Pará for environmental preservation and relevant services provided to the State.

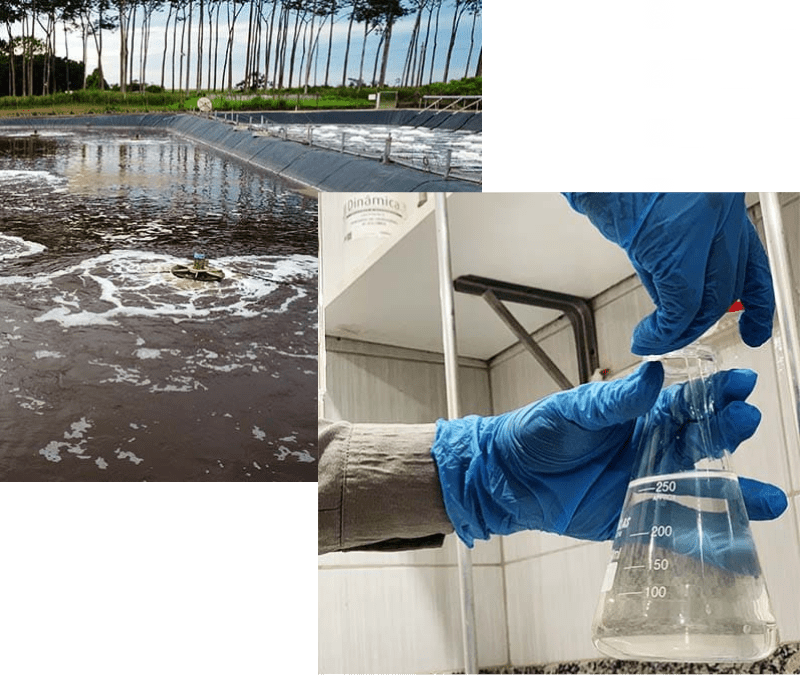

The responsibility for sustainable development goes beyond our reforestation. Today, 100% of all water used by our industry is reused. Flora has an Effluent Treatment Station with a treatment capacity of 60 m³ per hour, that is, it treats all the effluent used in the MDF production process and returns the treated effluent for use again in the production process. In this way, we minimize possible damages to the environment, arising from the capture by wells.

Water is present in 80% of the processes at our factory, from washing the chip to cooking the fiber that will be crushed to produce MDF. In addition, our plant works with energy generated by our own thermoelectric plant, using biomass and demineralized water to generate steam. Our demineralized water is also produced within our facilities, through the process of ion exchange, a rigorous process in which more than 130 analyzes are carried out daily to guarantee the quality of our water.